Business Analytics

Services designed to optimize your solution while minimizing vulnerabilities and risk

Optimize Performance & Reliability while Decreasing Risk

Business Analytics Services

Improve Repeatability and Reduce Vulnerabilities of Your Solution with Business Analytics Services

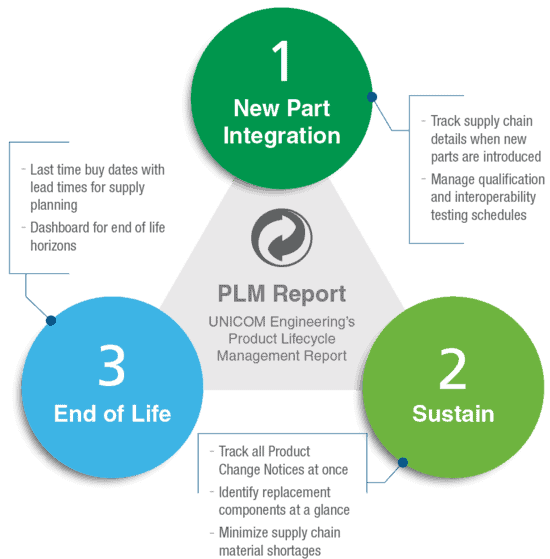

Product Lifecycle Management Report

Provides a complete picture of component PLM information and activities.

Read more about product lifecycle management reportCustomer Web Portal

Visibility and control of your business online through a secure web portal.

Read more about customer web portalCustomer Experience Reporting Service

Make informed decisions reducing your risk and increasing end-user satisfaction.

Read more about customer experience reporting serviceProduct Lifecycle Management report

UNICOM Engineering takes a holistic approach to Product Lifecycle Management (PLM), enabling you to manage each phase of your solution strategically. The basis of the system is the data that relates to the design, production, support, end of life, and potential transition plans to new technology, along with a proactive and comprehensive approach that ensures predictable, repeatable builds and reduces the many risks and costs associated with change.

A vital tool for our Product Lifecycle Management system is the Product Lifecycle Management (PLM) Report, which combines data from various infrastructure tools and databases, including Oracle and Agile, to provide a complete picture of component PLM information and activities. The report is designed to provide a timeline view of changes associated with each component used in a solution allowing the customer to collect data and react accordingly to prevent shipping delays. Sometimes, supply chain issues may arise for components such as memory and hard disk drives; the report may provide alternate (second source) manufacturer parts for applicable items.

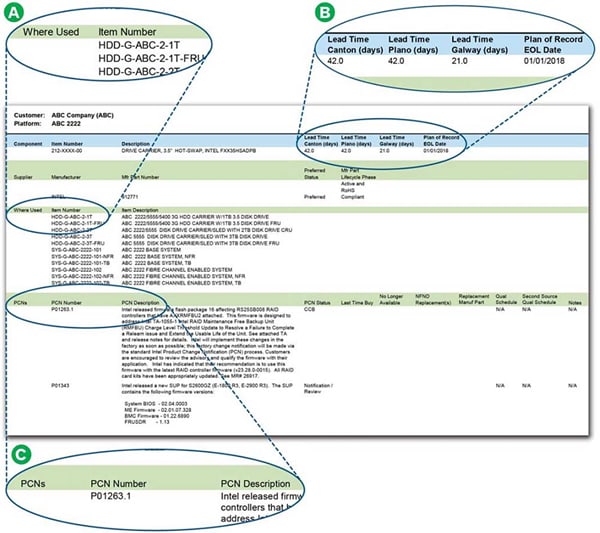

Customer portal

Lifecycle Management Report provides a comprehensive snapshot of the solution lifecycle to the component level. See below example:

- Where used data provides complete visibility to component usage across platforms for quick reference and change control.

- Business Intelligence provided through lead time, and EOL data enables accurate supply and transition planning of existing and next-gen solutions.

- The Product Change Notification (PCN) portion of the report serves as a repository of technology partner notifications regarding updates and lifecycle changes to components.

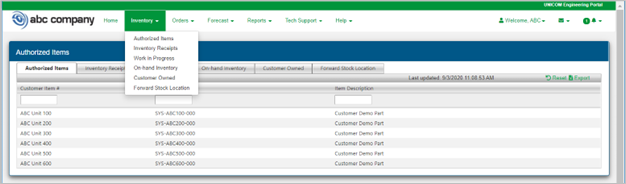

Customer web portal

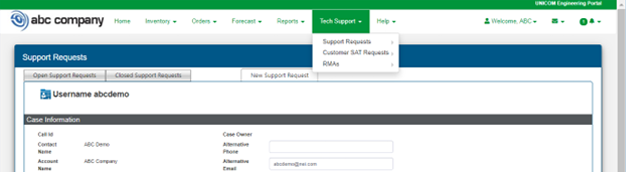

UNICOM Engineering’s customer portal provides visibility and control of your business online through a secure web portal that reports the status of inventory, tracks orders and shipments, manages forecasts, and produces reports. The portal serves as a primary access point to information and to view the status of products and orders in real-time.

The portal shows the status of current shippable products, finished goods, and Work in Progress (WIP) by location–enabling customers to plan and execute location-based distribution. Having this information at your disposal allows you to respond to sales demand in a more timely manner.

The portal offers multiple ways to view your business information. You can see the information by PO, ship date, or serial number. You can request and generate reports that include information on RMAs, open orders, WIP, shipments, and evaluation equipment.

Forecasting

As a vital step in securing inventory and driving manufacturing plans to address demand, our Account Managers work with our Project Managers to develop build forecasts (by SKU if possible). Customer forecasts are accessible through the portal for review and evaluation.

Inventory management

The Partner Portal is key to managing and tracking manufacturing cycles and inventory levels at UNICOM Engineering’s various plants and depots. The portal provides access to inventory sorted by customer-owned, finished goods and Work in Progress (WIP) by location—better enabling customers to commit to sell/ship on time.

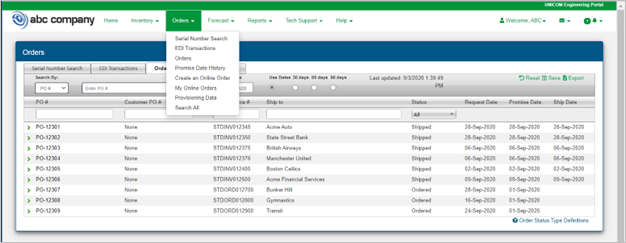

Order and shipment tracking

Once an order is placed, customers can track and report the status of individual shipments. The portal provides valuable information, including the carrier, tracking number(s), and associated freight charges. Retrieve data by ship date or PO number, and results provide details down to the serial number of each part. This level of asset management is critical to customers who use serial numbers and MAC addresses to establish license keys for the software loaded on each device.

Order and shipment tracking enables customers to:

- Pro-actively monitor and share shipping information with their customers

- Plan the deployment of installation/service technicians

- Obtain proof of purchase shipment for regulatory and audit purposes

- Initiate invoice processes

Operational reports

A series of reports are available to customers via the portal, including Open Order Summary, Shipment Summary, RMA Activity, and Detailed RMA Activity reports. In addition to viewing these via the portal, many of these reports are available to be received via an HTML email for users who choose to subscribe to such emails.

Technical support

You can enter new support tickets, view open/closed tickets, and receive support help using this section of the portal. Here is an example of the screen for entering a new support ticket.

Customers can quickly and easily:

- Place a new support request

- View open and closes requests

- View RMA activity

- Place and view customer SAT requests

Refurbishment program

UNICOM Engineering offers a refurbishment program whereby used inventory can be returned to our facilities, refurbished and restocked for demonstration and evaluations, pilot programs, proof of concepts, or other business needs. The portal provides visibility into this inventory as well, allowing customers to view quantities, locations, and current conditions of that inventory.

Customer Experience Reporting service

Supporting solutions in the field can quickly erode profits and decrease end-user satisfaction if you are unable to find a rapid resolution to issues. UNICOM Engineering’s Customer Experience Reporting service provides the business analytics required to make informed decisions reducing your risk and increasing end-user satisfaction. We follow a systematic approach to troubleshooting incidents in the field and capture vital data points throughout the process.

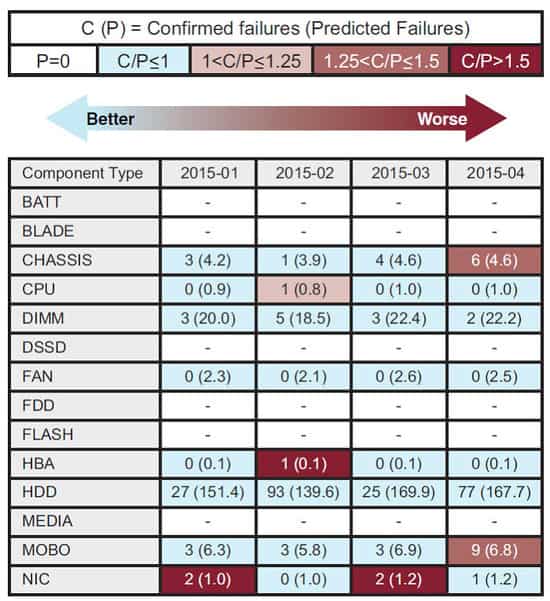

Our Customer Experience Reporting services aggregate the data into an easy to use dashboard providing early indicators of product issues in the field. It further provides a lifecycle view over time, revealing potential trends and quality improvement opportunities. As components within the solution approach their end of life, this data can be used to predict the necessary inventory and resources required to support contractual service levels.

The dashboard defined

The Customer Experience Dashboard is a tool that enables visibility to the incident and confirmed failure data. It tracks subcomponent and provides a visual and numeric representation of platform performance. Depending on the service level you choose, the dashboard can provide the following:

- Incident, Field Repair, Return, and Confirmed

- Failure Ratios by month

- Actual to predicted failure rates

- Visibility to overall portfolio or individual product line failures

- Failure reports for each phase of the product lifecycle

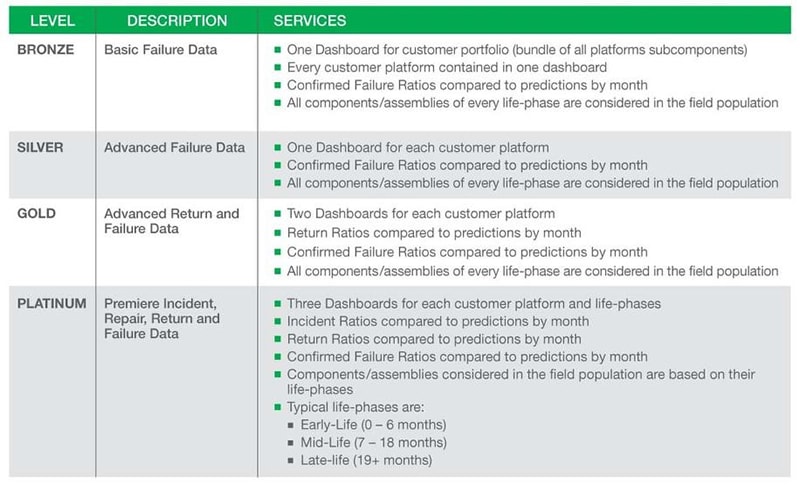

Service level to meet your needs

Each organization has different requirements for data and reporting. The following service levels are available to ensure you only invest in the required data.

Helpful Resources

Datasheet

Services designed to optimize your solution while minimizing vulnerabilities and risk

Discover Why Leading Technology Companies Trust UNICOM Engineering

The quicker we start to engage, the faster this can happen. We’ve provided some baseline information above, but we are much more engaging in person. Let’s discuss the technology and services that will optimize your application and drive performance.

Schedule a consultation